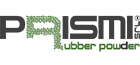

Accredited Lab Test Acoustic Underlay MGE 3: Impact Noise Reduction UNI EN ISO 10140-3

Accredited Lab Test Acoustic Underlay MGE 3: Impact Noise Reduction UNI EN ISO 10140-3:2021

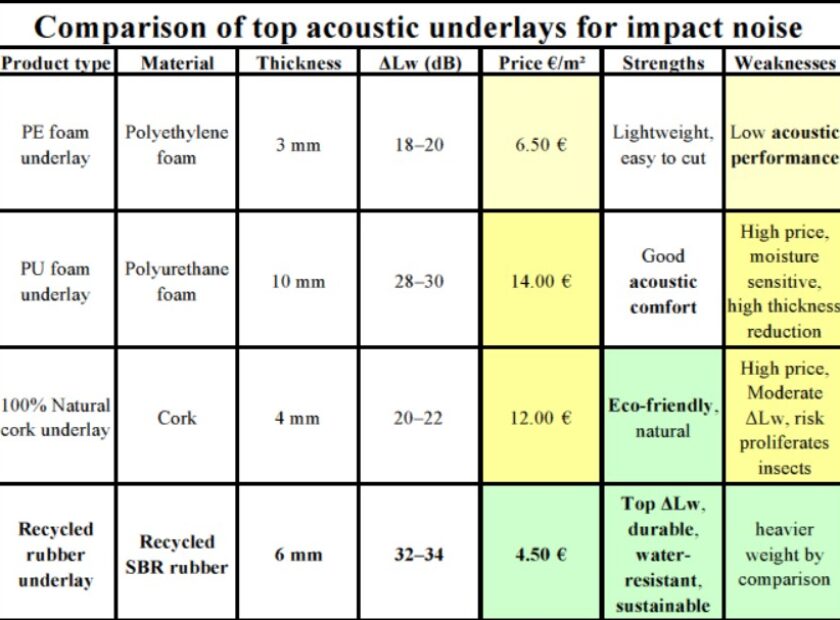

The MGE 3 acoustic underlay is a roll of densified recycled rubber bonded with polyurethane resins, designed for sound insulation under screed in construction, with certified impact noise reduction ΔLw 18 dB according to UNI EN ISO 10140-3:2021.

Analyzing the accredited test report (No. 437868, dated February 18, 2026), the MGE 3 excels in building applications due to its nominal density of 750 kg/m³ and 3 mm thickness, effectively reducing low-frequency vibrations (100-5000 Hz). This makes it ideal for distributors seeking EU-compliant solutions, balancing sustainability (recycled rubber) and performance, with low measurement uncertainty (U(ΔLw) ±1.4 dB) for reliability in international projects.

Product Description MGE 3: Effective Under Screed Sound Insulation

The MGE 3 acoustic underlay, from the PRISMI MGE brand, is a roll of densified recycled rubber bonded with polyurethane resins, ideal for attenuating impact noises under screed in building contexts.

With typical dimensions of 1000 mm width and 3 mm thickness, it offers a surface mass of 2.3 kg/m² and a nominal density of 750 kg/m³. Laid under a 50 mm sand-cement screed (mass 100 kg/m²), it creates a floating system that acoustically insulates heavy floors, reducing transmitted impact noise.

From the test report, the product was tested on a 5×5.5 m reference floor with 150 mm thickness, with an effective acoustic surface of 10.8 m². Installed on January 16, 2026 by accredited staff, it showed resistance with no visible damage after tests, with a 21-day screed curing period.

For building material distributors, MGE 3 represents a sustainable and high-performing solution, compliant with European standards for under screed sound insulation.

Accredited Lab Test Results

The tests conducted according to UNI EN ISO 10140-3:2021, UNI EN ISO 10140-1:2021, and UNI EN ISO 717-2:2021 measured the impact noise reduction on a normalized heavy floor. Using a standardized tapping machine (Nor 277) in 6 positions, sound pressure levels were detected in 1/3-octave bands from 100 to 5000 Hz.

Key results in table:

Frequency (Hz) | Ln,0 (dB) | ΔL (dB) | νeff | k | U (dB) |

100 | 61.6 | 5.0 | 9 | 2.26 | 3.3 |

125 | 69.7 | 7.2 | 9 | 2.26 | 2.9 |

160 | 69.6 | 5.3 | 7 | 2.36 | 2.4 |

… | … | … | … | … | … |

5000 | 72.3 | 43.5 | 5 | 2.57 | 2.2 |

Rating indices: ΔLw = 18 dB, with uncertainty U(ΔLw) = ±1.4 dB. Ln,r,w = 60 dB, confirming effective reduction, especially at low frequencies where impact noises are most annoying.

Environmental conditions (temperature 24-25°C, humidity 42-50%) and measurement uncertainty (per JCGM 100:2008) ensure reliability for real applications.

Applications and Benefits for Construction

The MGE 3 acoustic underlay under screed is perfect for residential and commercial buildings, laid under screed to insulate floors from impact noises. Typical applications: renovations, new builds with underfloor heating or floating floors. Benefits:

- Sustainability: Recycled rubber, reduces environmental impact.

- Performance: Impact noise reduction up to 43.5 dB at 5000 Hz, EU compliant.

- Easy Installation: Side-by-side rolls, total thickness 53 mm with screed.

- Durability: No damage post-test, withstands loads up to 100 kg/m².

For product details, visit our acoustic rubber rolls page.

Why Choose MGE 3 for International Distributors

In a construction market increasingly focused on acoustic comfort, MGE 3 offers high conversions for large distributors. Accredited tests (ACCREDIA) ensure compliance with European standards, facilitating sales in the UK, USA, UAE, and beyond. Ideal for B2B projects, with emphasis on sustainability and measured performance.

Conclusions on the Prismi MGE 3 acoustic mat

The MGE 3 acoustic underlay under screed, with its lab test results, is a top solution for sound insulation under screed. Contact us for samples or quotes for distributors.

Frequently Asked Questions on the MGE 3 Acoustic Underlay Lab Test

What does ΔLw 18 dB mean in the MGE 3 acoustic underlay test?

ΔLw indicates the weighted reduction in normalized impact sound pressure level on a reference floor. For MGE 3, it’s 18 dB, ideal for residential buildings

How to install an acoustic underlay under screed like MGE 3?

Lay the rolls side by side on heavy floor, cover with 50 mm sand-cement screed after curing. Avoid acoustic bridges

Is the MGE 3 underlay compliant with EU norms?

Yes, tested UNI EN ISO 10140-3:2021, with compliance for European sound insulation regulations

What's the difference between under screed and under parquet sound insulation?

Under screed reduces structural noises; under parquet is for light finishes. MGE 3 excels in the former

How much does an acoustic underlay like MGE 3 cost for large distributors?

Depends on volume; contact for B2B quotes. Offers high ROI due to durability

Are lab tests reliable for real applications?

Yes, with low uncertainty (±1.4 dB) and controlled environmental conditions, simulating building uses