Acoustic rubber wall break strip MGEF for professional sound insulation

The MGEF acoustic wall break strip is a professional solution for the acoustic decoupling of walls and vertical structures.

The Prismi range of acoustic rubber rolls is completed by Mini Roll MGEF, specifically designed to reduce vibration transmission, impact noise and structure-borne sound.

Using the same technology as the MGE acoustic underlay, the MGEF strip acts as an anti-vibration strip for partition walls, improving sound insulation performance in both residential and public buildings.

MGEF acoustic wall break strip description

The MGEF insulating strip is an anti-vibration wall break band designed for the structural decoupling of partition walls, preventing sound transmission through building structures.

MGEF stands for Rubber Insulation Mat for Construction – Strip Format and is manufactured using:

- selected recycled rubber granules

- polyurethane resin binders

- controlled density of 750 kg/m³

Technical specifications

- Available thicknesses: 3 – 5 – 6 mm

- Certified recycled content: >92% (A+ rating)

- Widths: 100 – 150 – 200 – 250 – 300 – 400 mm

- Roll lengths: 20 m – 12 m – 10 m

Thanks to its high elasticity and compressive strength, MGEF is an acoustic isolation wall break strip essential for achieving high levels of sound insulation in partition walls made of timber or masonry.

Application of the MGEF insulating strip

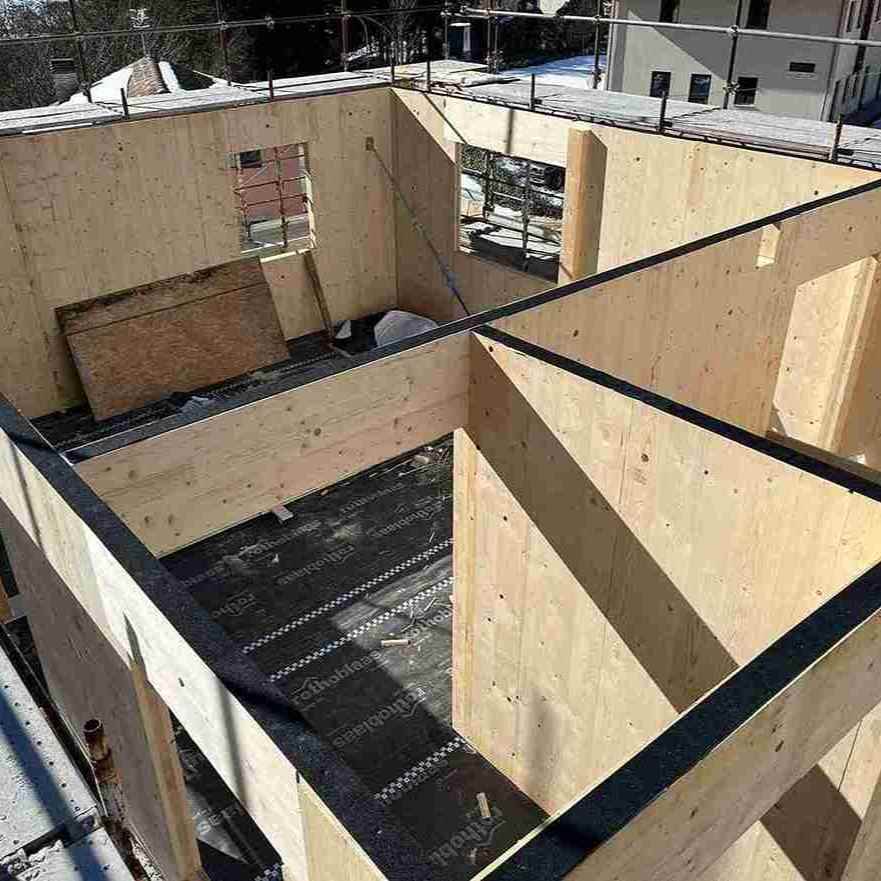

The MGEF acoustic strip is installed beneath vertical walls, in continuity with the acoustic floor underlay, to fully separate structural elements and eliminate acoustic bridges.

Recommended applications include:

- masonry partition walls

- timber frame walls

- mixed construction systems

- residential and public buildings

Correct installation improves airborne sound insulation and significantly reduces impact noise transmission.

Why choose the MGEF acoustic wall break strip by Prismi

Choosing the MGEF wall break strip means relying on a Made in Italy professional solution, engineered for high-performance acoustic insulation systems.

Key advantages

- Full control of the production process

From internally recycled rubber to final packaging. Environmental and quality certifications ensure responsible and traceable manufacturing. - Certified acoustic performance

Acoustic performance values are tested by Accredia-accredited laboratories, providing reliable and objective data for designers and acoustic consultants. - Custom manufacturing options

For large quantities, custom wall break strips can be produced in specific widths and lengths, including private labeling.

Installation of the MGEF anti-vibration strip

The MGEF acoustic wall break strip is installed directly on the raw concrete slab, beneath partition walls.

- Timber walls: mechanically fixed using staples

- Masonry walls: simply laid on the slab without adhesives

Proper installation is essential to achieve the expected performance of acoustic wall decoupling systems.

FAQ – MGEF acoustic wall break strip

Are wall break strips essential for acoustic insulation of partition walls?

Yes. Wall break strips are essential to prevent sound transmission through vertical structures. Without an acoustic decoupling strip, acoustic bridges significantly reduce insulation performance and make future corrective work costly and complex.

Are acoustic wall break strips available in different thicknesses?

Yes. MGEF acoustic wall break strips are available in multiple standard thicknesses and can be customized on request depending on project requirements and order quantities.

Does the acoustic wall break strip need to be fixed to the structure?

It depends on the wall type.

For timber partitions, the strip is mechanically fixed using staples. For masonry walls, it is simply laid on the concrete slab. No adhesives are required.

When should the MGEF wall break strip be used?

The MGEF wall break strip should be used in all construction systems where vertical walls must be acoustically separated from the slab, both in residential and public buildings, to ensure high acoustic insulation performance.